Industry News

-

Machining accuracy knowledge that must be mastered in machining

Machining accuracy is the degree to which the actual size, shape and position of the surface of the machined parts conform to the ideal geometric parameters required by the drawings. The ideal geometric parameter, for the size, is the average size; for the surface geometry, it is the absolute cir...Read more -

Process flow of stainless steel precision casting

In our life, there are many alloy materials used that are difficult to machine, and the shapes of the parts are so complex that they cannot or are difficult to manufacture by other methods, especially in aerospace and other fields. Stainless steel precision casting, also known as investment preci...Read more -

Ten benefits of precision casting

Precision casting technology is one of the most popular metal forming techniques in modern times. In this article, we’ll walk you through the many benefits of precision casting and find out why it’s often the first choice for manufacturers looking for high-precision, accurate, high-qu...Read more -

Casting and pouring may seem simple, but there are many details. Remember to pay attention to these points in production!

There are certain specifications and requirements for lost foam casting. The following aspects should be paid attention to in the molding process: silica sand is generally used in lost foam casting, and its silica content is required to be more than 85%~90%. In terms of air permeability and refra...Read more -

24 kinds of metal materials and their characteristics commonly used in machinery and mold processing!

1. 45-high-quality carbon structural steel, the most commonly used medium-carbon quenched and tempered steel Main features: The most commonly used medium carbon quenched and tempered steel, with good comprehensive mechanical properties, low hardenability, and easy to crack during water quenching....Read more -

CNC lathe machining process skills

CNC lathe is a kind of high-precision and high-efficiency automatic machine tool. The use of CNC lathe can improve machining efficiency and create more value. The emergence of CNC lathe has made enterprises get rid of the backward processing technology. The technology of CNC lathe processing is c...Read more -

11 steps that must be understood in gear processing

Gear machining is an extremely complex process. Only through the use of the right technology can efficient production be possible. Every part of the production process must also reach extremely precise dimensions. The gear processing cycle includes ordinary turning → hobbing → gear shaping → shav...Read more -

Seven Ways to Detect the Positioning Accuracy of CNC Machine Tools

The positioning accuracy of a CNC machine tool refers to the position accuracy that can be achieved by the movement of each coordinate axis of the machine tool under the control of the CNC device. The positioning accuracy of a CNC machine tool can be understood as the motion accuracy of the machi...Read more -

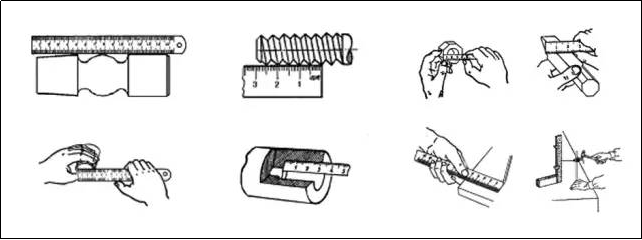

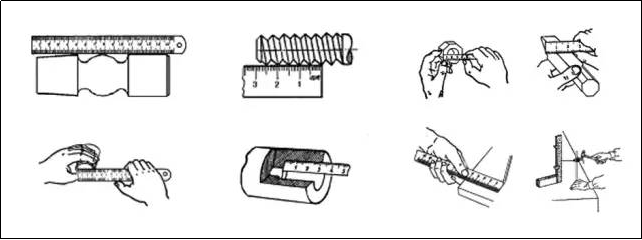

Encyclopedia of various measuring tools!

Chapter 1 Steel rulers, internal and external calipers and feeler gauges 1. Steel ruler The steel ruler is the simplest length measuring tool, and its length is available in four sizes: 150, 300, 500 and 1000 mm. The picture below is a commonly used 150 mm steel ruler. The steel ruler is used ...Read more -

Seven kinds of thread processing methods are explained in detail!

Thread processing is a method of processing various internal and external threads with thread processing tools. 1. Thread cutting Generally refers to the method of machining threads on a workpiece with a forming tool or an abrasive tool, mainly including turning, milling, tapping, threading grin...Read more -

Why do mechanical parts need to be heat treated?

In order to make the metal workpiece have the required mechanical properties, physical properties and chemical properties, in addition to the reasonable selection of materials and various forming processes, heat treatment processes are often indispensable. Steel is the most widely used material i...Read more -

How to calculate speed and feed?

Each tool adopts different processing parameters for different processing materials. In the field of milling, tool manufacturers develop more targeted coating technologies by optimizing tool materials to improve machining efficiency. Through the combination of various elements in the material, we...Read more